Gigabyte Radeon RX Vega 64 Gaming OC 8G Review — Tom’s Hardware

Skip to main content

When you purchase through links on our site, we may earn an affiliate commission. Here’s how it works.

Early Verdict

Gigabyte’s Radeon RX Vega 64 Gaming OC 8G began life as an Aorus-branded stunner, but had to be pared back in the face of supply issues from AMD. What remains is still a very fast gaming board, albeit with a more budget-oriented cooler. Unfortunately, limited availability means there aren’t many to go around.

Pros

- +

Noise-optimized design

- +

Well-implemented heat pipe direct touch cooler

- +

Great 2560×1440 gaming performance

- +

Six display outputs

- +

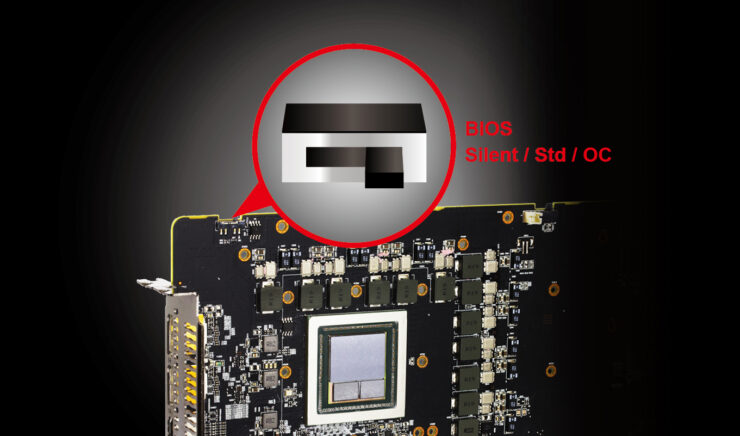

Improved fan speed profile via recent BIOS update

Why you can trust Tom’s Hardware

Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

Today’s best Gigabyte RX Vega 64 Gaming OC deals

Features & Specifications

A few weeks back, we published our Sapphire Radeon RX Vega 64 Nitro+ Review, introducing the first third-party Vega-based card to land in our labs. Compared to that board, and like the Radeon RX Vega 56 Gaming OC 8G we reviewed previously, Gigabyte’s Radeon RX Vega 64 Gaming OC 8G is more understated, featuring easier-to-manage weight and dimensions. It’s almost like this card was designed to be ordinary-looking, so as not to generate demand that Gigabyte wouldn’t be able to satisfy. Nevertheless, this is a good example of a bread-and-butter solution that covers all of the bases and still offers a different approach than AMD’s reference implementation.

Specifications

Market & Availability

According to our sources, AMD’s board partners have only received a few thousand Vega 10 GPUs. Thus, a general shortage of packages is preventing anyone from mass-producing notable quantities of Radeon RX Vega 56 or 64 cards. It’s simply not possible to start and stop a production line over and over again. It costs too much time and money.

It’s simply not possible to start and stop a production line over and over again. It costs too much time and money.

We were lucky to get our hands on a sample of Gigabyte’s Radeon RX Vega 64 Gaming OC 8G. Buying a card of our own was the only way to get one into into the German lab. Here in the U.S., this is a mythical creature. Nobody has it for sale, and the only references online come from Gigabyte’s site or product announcement news stories.

Unboxing, Look & Feel

Weighing just 1006g, Gigabyte’s card is almost 600 grams lighter than Sapphire’s Radeon RX Vega 64 Nitro+. This implementation is also considerably more compact, yielding a length of just 27.8cm, a height measurement of 13cm, and 4.7cm of width.

Two counter-rotating fans, each with a diameter of 9.5cm, are positioned inside 10cm openings. According to Gigabyte, its unique fan blade design splits airflow and guides it through curves on the fan surface, improving flow compared to traditional fans. Naturally, we’ll test the efficacy of those claims shortly.

Naturally, we’ll test the efficacy of those claims shortly.

The backplate doesn’t feature an Aorus logo, which was present on a pre-production model we briefly had our hands on. A copper insert placed on the back of the package is thermally isolated from this plate. Both components do play a role in cooling, though. Not pictured is a heat pipe that snakes around under the backplate, though we’ll cover that in more depth, too.

Plan for an extra 5mm of clearance (at least) behind the Radeon RX Vega 64 Gaming OC 8G. This may cause problems on some motherboards, particularly if the heat sink/backplate intrude on an occupied expansion slot or large CPU cooler.

A peek in from the bottom shows that Gigabyte optimized the shape of its vertically-oriented fins. The slight tilt and wave shape are meant to create more efficient airflow, and thus improve cooling.

Up top, it’s apparent that Gigabyte paid close attention to cost. There are no RGB lighting effects or other gimmicks. Instead, you get simple injection-molded plastic and printed orange-colored highlights. The white Gigabyte logo is simply printed on. And similar to AMD’s reference design, Gigabyte only requires a pair of eight-pin auxiliary power connectors.

Instead, you get simple injection-molded plastic and printed orange-colored highlights. The white Gigabyte logo is simply printed on. And similar to AMD’s reference design, Gigabyte only requires a pair of eight-pin auxiliary power connectors.

The closed back side doesn’t reveal much. We catch a mere glimpse of two 8mm and three 6mm heat pipes, along with the fans’ cable. On the board itself, we see solder pads for additional components (RGB output, perhaps?) that were obviously abandoned at some point during development.

The I/O bracket is interesting because it features six connectors, rather than the reference design’s five. Three HDMI 2.0 ports and three DisplayPort 1.4 outputs are available simultaneously, allowing you to connect six monitors in an Eyefinity array.

In accordance with AMD’s guidelines for clock rates, Gigabyte increased the Radeon RX Vega 64 Gaming OC 8G’s base and Boost frequencies significantly. Unfortunately, the maximum Boost value is unrealistic; it cannot be sustained within the board’s power limit.

In comparison to the relevant reference cards the data looks as follows:

Swipe to scroll horizontally

| Model | Radeon RX Vega 64 | Gigabyte RX Vega 64 Gaming OC | Radeon RX Vega 56 | GeForce GTX 1070 Ti | GeForce GTX 1080 |

|---|---|---|---|---|---|

| GPU | Vega 10 | Vega 10 | Vega 10 | GP104 | GP104 |

| Die Size | 486 mm² | 486 mm² | 486 mm² | 314 mm² | 314 mm² |

| Transistors | 12. 5 billion 5 billion |

12.5 billion | 12.5 billion | 7.2 billion | 7.2 billion |

| Base/Boost Clock Rate | 1247/1546 MHz | 1274/1630 MHz | 1156/1471 MHz | 1607/1683 MHz | 1607/1733 MHz |

| Shaders/SIMDs | 4096/64 | 4096/64 | 3584/56 | 2432/19 | 2560/20 |

| Texture Units/ROPS | 256/64 | 256/64 | 224/64 | 152/64 | 160/64 |

| Pixel Fill Rate | 79.8 GPix/s | 81.5 GPix/s | 74 GPix/s | 102. 8 GPix/s 8 GPix/s |

114.2 GPix/s |

| Texture Fill Rate | 319.2 GT/s | 326.1 GT | 258.9 GT/s | 244 GT/s | 257.1 GT/s |

| Memory Interface | 2048-bit | 2048-bit | 2048-bit | 256-bit | 256-bit |

| Memory Type | HBM2 | HBM2 | HBM2 | GDDR5 | GDDR5X |

| Memory Bandwidth | 484 GB/s | 484 GB/s | 410 GB/s | 256 GB/s | 320 GB/s |

| Memory Speed | 1. 89 Gb/s 89 Gb/s |

1.89 Gb/s | 1.6 Gb/s | 8 Gb/s | 10 Gb/s |

| Memory Size | 8GB | 8GB | 8GB | 8GB | 8GB |

| DX12 Feature Level | 12_1 | 12_1 | 12_1 | 12_1 | 12_1 |

| PCIe Power Connectors | 2x 8-Pin | 2x 8-Pin | 2x 8-Pin | 1x 8-pin | 1x 8-pin |

| TDP | 295W | 295W | 210W | 180W | 180W |

Test System & Measurement Methods

We introduced our new test system and methodology in How We Test Graphics Cards. If you’d like more detail about our general approach, check that piece out. We’ve upgraded the CPU and the cooling system since then to make sure that nothing’s holding back graphics cards as fast as this one.

If you’d like more detail about our general approach, check that piece out. We’ve upgraded the CPU and the cooling system since then to make sure that nothing’s holding back graphics cards as fast as this one.

The hardware used in our lab includes:

Swipe to scroll horizontally

| Test System | |

|---|---|

| Hardware | Intel Core i7-6900K @ 4.3 GHzMSI X99S XPower Gaming TitaniumCorsair Vengeance DDR4-32001x 1TB Toshiba OCZ RD400 (M.2, System SSD)2x 960GB Toshiba OCZ TR150 (Storage, Images)be quiet Dark Power Pro 11, 850W PSUWindows 10 Pro (All Updates) |

| Cooling | Alphacool Eisblock XPX5x be quiet! Silent Wings 3 PWM (Closed Case Simulation)Thermal Grizzly Kryonaut (Used when Switching Coolers) |

| Case | Lian Li PC-T70 with Extension Kit and ModsConfigurations: Open Benchtable, Closed Case |

| Monitor | Eizo EV3237-BK |

| Power Consumption Measurement | Contact-free DC Measurement at PCIe Slot (Using a Riser Card)Contact-free DC Measurement at External Auxiliary Power Supply CableDirect Voltage Measurement at Power Supply2 x Rohde & Schwarz HMO 3054, 500 MHz Digital Multi-Channel Oscilloscope with Storage Function4 x Rohde & Schwarz HZO50 Current Probe (1mA — 30A, 100 kHz, DC)4 x Rohde & Schwarz HZ355 (10:1 Probes, 500 MHz) 1 x Rohde & Schwarz HMC 8012 Digital Multimeter with Storage Function |

| Thermal Measurement | 1 x Optris PI640 80 Hz Infrared Camera + PI Connect Real-Time Infrared Monitoring and Recording |

| Noise Measurement | NTI Audio M2211 (with Calibration File, Low Cut at 50Hz) Steinberg UR12 (with Phantom Power for Microphones) Creative X7, Smaart v. 7 Custom-Made Proprietary Measurement Chamber, 3.5 x 1.8 x 2.2m (L x D x H) Perpendicular to Center of Noise Source(s), Measurement Distance of 50cm Noise Level in dB(A) (Slow), Real-time Frequency Analyzer (RTA) Graphical Frequency Spectrum of Noise 7 Custom-Made Proprietary Measurement Chamber, 3.5 x 1.8 x 2.2m (L x D x H) Perpendicular to Center of Noise Source(s), Measurement Distance of 50cm Noise Level in dB(A) (Slow), Real-time Frequency Analyzer (RTA) Graphical Frequency Spectrum of Noise |

MORE: Best Graphics Cards

MORE: Desktop GPU Performance Hierarchy Table

MORE: All Graphics Content

- 1

Current page:

Features & Specifications

Next Page Board & Power Supply

Tom’s Hardware is part of Future US Inc, an international media group and leading digital publisher. Visit our corporate site .

©

Future US, Inc. Full 7th Floor, 130 West 42nd Street,

New York,

NY 10036.

ROG-STRIX-RXVEGA64-O8G-GAMING | ROG-STRIX-RXVEGA64-O8G-GAMING | Gaming Graphics Cards|ROG

OUTSHINE

THE COMPETITION

ROG Strix RX VEGA64 gaming graphics cards are packed with exclusive ASUS technologies, including all-new MaxContact Technology that is 2X more contact with GPU for improved thermal transfer, and Patented Wing-Blade IP5X-Certified Fans for maximum airflow and longer fan lifespan. While ASUS FanConnect II features 4-pin, hybrid-controlled headers connected to system fans for optimal system cooling. ASUS Aura Sync RGB LED synchronization enables a gaming system personalization and VR-friendly HDMI ports let gamers easily enjoy immersive virtual reality experiences. ROG Strix RX VEGA64 also has GPU Tweak II with XSplit Gamecaster that provides intuitive performance tweaking and instant gameplay streaming.

While ASUS FanConnect II features 4-pin, hybrid-controlled headers connected to system fans for optimal system cooling. ASUS Aura Sync RGB LED synchronization enables a gaming system personalization and VR-friendly HDMI ports let gamers easily enjoy immersive virtual reality experiences. ROG Strix RX VEGA64 also has GPU Tweak II with XSplit Gamecaster that provides intuitive performance tweaking and instant gameplay streaming.

PERSONALIZED GAMING STYLE

ASUS Aura Sync

Outshine The Competition

Featuring Aura RGB Lighting on both the shroud and backplate, ROG Strix graphics cards are capable of displaying millions of colors and six different effects for a personalized gaming system. ROG Strix graphics cards also feature ASUS Aura Sync, RGB LED synchronization technology that enables complete gaming system personalization when the graphics card is paired with an Aura-enabled gaming motherboard.

Experience Aura

Color and Brightness

Experience Aura Lighting Effect

Static

Always on

Breathing

Fades in & out

Strobing

Flashes on & off

Color cycle

Fades between the colors of the rainbow

Music effect

Pulses to the beat of your music

GPU temperature

Changes color with GPU load

LEVEL UP PERFORMANCE

GAME COOL

AND PLAY SILENT

40% More Heat Dissipation Area

20%* Cooler and 3X Quieter Gaming Performance

New ROG Strix graphics are constructed with a 2.5-slot width, providing 40% more heat sink surface area for heat dissipation compared to previous 2-slot designs for dramatically cooler and quieter performance.

*Performance may vary by model.

**Images for reference only.

MaxContact Technology

2X More Contact with GPU for Improved Thermal Transfer

MaxContact is an industry-first GPU cooling technology, featuring an enhanced copper heat spreader that directly contacts the GPU. MaxContact utilizes precision machining to provide a surface that makes up to 2X more contact with the GPU than traditional heat spreaders, resulting in improved thermal transfer.

MaxContact utilizes precision machining to provide a surface that makes up to 2X more contact with the GPU than traditional heat spreaders, resulting in improved thermal transfer.

Patented Wing-Blade Design

Max Air Flow with 105% More Air Pressure

Patented wing-blade fans delivers maximum air flow and 105% greater static pressure over the heat sink, while operating at an up to 3X quieter volume than reference cards.

0dB Technology

Game in Complete Silence

Innovative 0dB technology stops the fan completely when the GPU temperature remains below a set level*, letting you enjoy light gaming in complete silence.

*55°C for ROG Strix RX VEGA64

IP5X-Certified Dust Resistance

Longer Fan Lifespan

The fans in ROG Strix graphics cards are certified under the International Protection Marking (IP code) as IP5X dust resistant for improved reliability and a longer lifespan. This stringent certification process ensures ROG Strix graphics cards provide optimal fan performance, even under severe conditions.

ASUS FanConnect II

Optimal System Cooling

ASUS FanConnect II features two 4-pin, hybrid-controlled headers that can be connected to both PWM and DC system fans for optimal system cooling. The connected fans reference both the GPU and CPU, operating automatically based on the one with the higher temperature. A comprehensive set of tuning options allow you to tune fan speeds for efficient cooling.

* Image for reference only. Actual PC layout may vary.

GPU Tweak II lets you easily set these ASUS FanConnect II modes:

Auto mode:

Chassis fan speeds reference GPU temperatures and operate based on the default factory setting.

Manual mode:

Allows you to set a fixed speed for connected fans.

User-defined mode:

Allows you to set chassis fans to reference either the CPU or GPU temperature to determine rotational speed. Additionally, a smart, automatic calibration routine senses the controllable range of connected fans and allows you to fine-tune speeds for efficient cooling and low noise.

PREMIUM QUALITY AND

BEST RELIABILITY

Auto-Extreme Technology

Industry-only 100% Automated Production Process

All ASUS graphics cards are now produced using Auto-Extreme Technology, an industry-exclusive, 100% automated production process that incorporates premium materials to set a new standard of quality. Auto-Extreme Technology ensures consistent graphics card quality as well as improved performance and longevity. Since the introduction of Auto-Extreme technology, reliability has improved by 30%. This new manufacturing process is also environmentally friendly, eliminating harsh chemicals and reducing power consumption by 50%.

100% automation

Remove human fallibility from production

Fortify component

overclocking stability

Advanced and stringent

quality control

Advanced components design innovation

Smooth circuit board without sharp bumps

Flux-free production

12+1 Phase Super Alloy Power II

Enhanced Durability and Efficiency

ASUS engineers have integrated premium alloy components into their graphics card designs to reinforce overall reliability. Super Alloy Power II components greatly enhance efficiency, reduce power loss and achieve thermal levels that are approximately 50% cooler than previous designs.

Super Alloy Power II components greatly enhance efficiency, reduce power loss and achieve thermal levels that are approximately 50% cooler than previous designs.

*This image is for illustration only, actual board design may vary.

GEAR UP FOR ULTIMATE GAMING EXPERIENCE

VR-friendly HDMI Ports

Easily Enjoy Immersive Virtual Reality Experience

ROG Strix graphics cards have two HDMI ports for connecting a VR device and display at the same time, so you can enjoy immersive virtual reality experiences anytime without having to swap cables.

Ramp up your PC with

ASUS Beyond VR Ready.

Your Need for Speed, Fulfilled

The Best Combo Ultra-smooth Gameplay

AMD FreeSync™ technology resolves the communication issues between processor and monitor, eliminating image tears and choppiness for effortlessly smooth gameplay. With ROG Strix gaming graphics cards and ASUS MG gaming monitors, scenes appear instantly, objects look sharper, and gameplay is super smooth, giving you a stunning visual experience and a serious competitive edge.

Learn more about ASUS gaming monitors at here.

GAME YOUR WAY

GPU Tweak II with XSplit Gamecaster

Intuitive Performance Tweaking

Redesigned with an intuitive, all-new UI, GPU Tweak II makes overclocking easier and more visual than ever, while still retaining advanced options for seasoned overclockers. With one click, the new Gaming Booster function maximizes system performance by removing redundant processes and allocating all available resources automatically.

Learn more at here.

Gaming Booster

One-click Performance Up

Visual effects:

Boost your performance by turning off windows visual effects.

System Services:

Automatically or manually turn off windows services or process.

Memory Defragmentation:

Re-arrange & free your system memory without closing any processes.

XSplit Gamecaster

Instant Gameplay Streaming

An included 1-year XSplit Gamecaster premium license* — a $99 USD value — lets you easily stream or record gameplay via a convenient, in-game overlay. The overlay also displays GPU clock speed, temperature, and VRM usage, and has GPU Tweak II controls, so gamers can choose a gaming profile and boost performance with just one click.

The overlay also displays GPU clock speed, temperature, and VRM usage, and has GPU Tweak II controls, so gamers can choose a gaming profile and boost performance with just one click.

Learn more at here.

ROG Strix is the newest recruit into the Republic of Gamers. A series of specialized gaming gear designed for the rebel in all of us, Strix exemplifies ROG’s premier performance, innovative technology, and leading quality, but with its own confident and dynamic attitude. Featuring bold designs and bright colors, this exciting new series possesses a spirit of fierce individualism that charges every gaming experience with thrilling energy. ROG Strix equips players with the necessary speed and agility to dominate their game. A new generation of force has arrived. Join the Republic and experience the power of ROG Strix.

|

Direction «Applied Mathematics and Informatics» Department of Software Systems of Radioelectronic Equipment |

nine0013 | |||

|

Login

MIREA — |

||||

nine0037

Real-time operating systems

Teachers:

- BORISOV Nikolai Konstantinovich

Course objectives:

- to form knowledge on the architecture and purpose of modern operating systems, methods of intertask interaction (IPC) in multitasking operating systems, concepts and mechanisms related to ensuring the operation of hardware and software systems in real time;

nine0053 - to form the skills of multi-threaded programming of applications designed to work in real time in C ++;

- build skills in developing and debugging applications in the Momentics IDE (based on Eclipse).

Content of the discipline:

- Introduction to RTOS. OS kernel architecture. Types of RV tasks. Examples of real-time systems. RTOS examples: VxWorks, QNX Neutrino, FreeRTOS.

- Basic requirements for real-time real-time system and modes of «soft» and «hard» real time.

nine0053 - Overview of the POSIX standard, purpose and scope.

- POSIX Thread Synchronization Mechanisms by Execution Time, Purposes and Principles of Use

- Thread scheduling disciplines in QNX Neutrino. The concept of priority.

- QNX Neutrino RTOS architecture. General scheme of the system organization. Development software

- Overview of synchronous IPC mechanisms in modern operating systems using QNX Neutrino as an example

- Message mechanism. Basic concepts, algorithm of work. Impulses. State Diagram of Participant Processes

nine0053 - Signal mechanism in UNIX-like operating systems. Real time signals

- Designing the Resource Manager .

Algorithm of work and basic principles of developing QNX Neutrino device drivers

Algorithm of work and basic principles of developing QNX Neutrino device drivers

- Organization of work of the multithreaded resource manager. Thread pool. Implementing a client-server model using the QNX Neutrino API.

- The concept of interruption in hardware-software systems. Purpose and development of an interrupt handler (ISR). Interrupt handling methods in QNX Neutrino

nine0053 - QNX Neutrino time service. Real time clock (RTC) assignment in real time hardware systems.

Technologies used:

- Oracle VirtualBox

- QNX Neutrino SDP 6.6

- C++ 11/14

- POSIX API

- Standard template library

Real-Time Operating Systems

Course instructors:

- BORISOV Nikolai

0050

- understanding soft and hard realtime tasks;

- getting an introduction to RTOS development;

- understanding tasks scheduling in RTOS;

- making an overview of the basic IPC mechanisms in modern OS, making a focus for it’s real-time applications;

- making an overview of the RTOS architecture basic principles using QNX Neutrino as “almost-ideal” sample of microkernel-based full POSIX-compatbile OS;

- getting a practice in multithreading C++ resource managers development using IDE Momentics.

nine0053

Feedback

nine0134

VEGA Atomic Force Microscope for large specimens

VEGA Atomic Force Microscope for large specimens | NT-MDT SI

+1-480-493-0093

High-Performance AFM for Examining Large Samples

- Measurements of morphology, electrical, nanomechanical and magnetic properties with manometer spatial resolution on wafers up to 200 mm in diameter, large samples and arrays of samples

- Highest level of measurement automation

- The most complete set of modern AFM techniques, including high-speed hopping microscopy techniques

- Fast scan for routine flow measurements of structure morphology

The ‘s ultimate imaging performance is ensured by the use of built-in acoustic and vibration isolation, thermal stabilization, industry-leading optical acquisition sensitivity, and a unique probe scanning system design that achieves atomic resolution in routine measurements. nine0007

nine0007

50+ AFM methods are available in the basic configuration, including the HybriD method, , which allows you to carry out all the cutting-edge nanomechanical, electrical and magnetic studies.

ScanTronic™ intelligent algorithm for one-click optimization of scan parameters, enables perfect AM terrain measurements regardless of operator experience.

Automated testing of multiple samples using a simple user interface to create a point-by-point scan script and a database for stored acquired images.

Control of samples with dimensions up to 200×200 mm and thickness up to 40 mm at any point on the surface with a positioning accuracy of 1 µm.

Highly customizable : installation of additional optical equipment, development of specialized sample holders, integration with the transport system, automation of measurements and data analysis in accordance with customer requirements. nine0007

Productivity

Automated analysis of large samples and sample arrays with ultimate positioning accuracy

Automated analysis of large samples and sample arrays with ultimate positioning accuracy:

- All the usual procedures such as change of ROI, registration system setup, soft approach and setup scan settings are fully automated.

- The movements of the motorized XY table are correlated with the optical image, providing a positioning accuracy of 1 µm over an area of 200×200 mm. nine0053

- Continuous serial measurements of large samples or arrays of samples become simple and efficient with intelligent automation algorithms, a user interface for time-lapse AFM measurements and a database of stored images.

Ultimate resolution

Graphite grating atomic resolution, 6×6 nm

0176 of atomic resolution , as well as measurements with Z noise less than 30 pm .

The specially designed optical design of the has the lowest SNR (25 fm/√Hz) of the cantilever bend detection optical system among the commercial AFMs for larger samples.

The ultimate high-resolution measurement environment

High-resolution measurements require the exceptional level of acoustic and vibration isolation of AFM’s industrial environment. nine0007

nine0007

The built-in acoustic enclosure and active vibration protection system make the VEGA AFM ideal for demanding AFM measurements.

Thermal drift is a significant problem in long-term, high-resolution AFM measurements, especially on large AFMs with large mechanical parts. Removal of all fuel parts from the working volume and built-in thermal stabilization system with an accuracy of 0.05 °C allow reaching a value of thermal drift less than 0.2 nm/min.

Additional features

Custom sample holders

Design of ASM VEGA provides quick change of sample holders due to their three-point installation. At the request of the customer, unique holders of various types can be developed and manufactured specifically for the samples under study:

- vacuum plate holding system, including those made for a specific transport system;

- holders with specialized electrical contacts, with the ability to heat and control the temperature of the sample;

- and much more.

nine0052 fastening systems for arrays of the same type of samples;

Additional optical equipment correlated with the position of the AFM probe

Research tasks often require the installation of additional optical equipment:

- additional optical microscope with a resolution of up to 250 nm; nine0053

- Raman Spectrometry;

- ellipsometer;

- and others

It can be easily integrated into the AFM VEGA and correlated with the position of the AFM probe thanks to the XY-coordinate table with a movement accuracy of 1 µm.

Automation of measurement and data analysis

New algorithms for automation of measurements and data processing can be developed in accordance with customer requirements. nine0007

The most advanced set of AFM methods in the basic configuration

HybriD (HD) method:

- Quantitative nanomechanical measurements (KND) — mapping of Young’s modulus and adhesion work.

- Volumetric force spectroscopy — recording of force curves for each scan point

- HD Current AFM (HD T-ASM) — non-destructive current measurements

- HD Piezoresponse force microscopy (HD PFM) — non-destructive measurements of piezoresponse

- HD KZSM, HD CESM, HD SEM — single and multi-frequency electrostatic measurements

- HD MCM — magnetic measurements

Peptide nanotubes of diphenylalanine: relief, adhesion, D 2 C/DZ 2 , Lateral piecopulmonary phase (polarization direction), 8×8 μm

Multi-frequency electric measurements

- one and two-resistant amplitteum Electrostatic force microscopy

- Single and Dual Pass Amplitude and Phase Modulation Kelvin Probe Force Microscopy

- Single and Dual Pass Scanning Capacitive Force Microscopy

Relief, surface potential and dC/dZ self-assembly of F14h30 molecules on silicon, 1. 5×1.5 µm

5×1.5 µm

Complete list of AFM techniques available in basic configuration:

Contact AFM: Relief, Lateral force modulation , Spread resistance display, Current AFM

Amplitude modulation AFM: Relief, Phase, OS signal

HybriD AFM method: Relief, Young’s modulus, Adhesion work, Viscoelasticity, Conductivity, Piezoresponse force microscopy of soft and loose samples, ACM

Magnetic Force Microscopy: DC/AC Dual Pass, DC/AC Single Frame

Electrostatic Force Microscopy: Single and double pass AM, FM

Scanning capacitance force microscopy: dC/dZ and dC/dV mapping

Kelvin probe force microscopy:

Piezoresponse Force Microscopy and Switching Srectroscopy

Nanolithography: Volt, Current, Power

nine0047 Applications

The constant decrease in the size of the element base in microelectronics imposes a number of fundamental requirements on instrumentation. In recent years, atomic force microscopy (AFM) has de facto become an integral part of the production cycle at leading foreign enterprises in the microelectronics industry. Based on the experience of world leaders in the high-tech industry, we have created an atomic force microscope that allows us to solve key problems in this area. nine0007

In recent years, atomic force microscopy (AFM) has de facto become an integral part of the production cycle at leading foreign enterprises in the microelectronics industry. Based on the experience of world leaders in the high-tech industry, we have created an atomic force microscope that allows us to solve key problems in this area. nine0007

Key applications

Control of nanoroughness of semiconductor wafers, control of morphology of micro- and nanostructures, masks and semiconductor wafers

A low-noise scanning system and a variety of unique NT-MDT SR AFM probes allow measurements of the surface morphology of large-sized samples with a vertical resolution of 30 pm.

Research of mechanical and adhesive properties of masks in micro- and nanoscale

The unique HybriD AFM method allows the construction of distribution maps of the quantitative values of the Young’s modulus and adhesion with a spatial resolution of up to 10 nm.

Testing the quality of conductive layers

Using a conductive probe as an electrode, AFM VEGA has the ability to map the conductivity distribution with a spatial resolution of up to 30 nm.

Research of electromechanical properties of microelectromechanical systems (mems)

The method of piezoresponse force microscopy makes it possible to build distribution maps of the domain structure of piezoelectrics, calculate piezoelectric coefficients, and study the dynamic properties of MEMS.

Research and control of the magnetic structure of data storage systems

The ability to display the domain structure with a resolution of up to 30 nm using magnetic force microscopy makes AFM a unique tool for researching and controlling the production of various types of magnetic storage devices. nine0007

Layer-by-layer study of the morphology and electrostatic properties of finished products

AFM VEGA is equipped with the most advanced set of electrostatic surface analysis methods, which allows mapping properties such as permittivity, capacitance, doping, surface potential, space charge, etc.

Surface of solar panel element. Scan size 70×46 µm

SRAM surface potential. Scan size 2.5×1.6 µm

Polysilicon surface. Scan size 1.5×0.6 µm

HDD magnetic domains

Scan size 40×26 µm

Benefits of using AFM in the production cycle

The use of AFM allows for direct non-destructive testing of both the morphology of micro- and nanostructures and photoresistive masks, as well as the distribution of their electromagnetic, mechanical and chemical properties with high spatial resolution at the level of 10- 20 nm. In addition, due to the low cost of operation compared to electron microscopy, the competitiveness of the manufacturer increases due to a significant reduction in financial costs. nine0007

Special requirements for AFMs in the industry

- High level of automation

Due to the high level of automation, ACM VEGA requires minimal involvement of the plant operator. This significantly reduces the requirements for staff qualifications.

This significantly reduces the requirements for staff qualifications. - Reliability

ACM VEGA uses components with long MTBF from the world’s leading manufacturers. However, in the event of equipment failure, the modular design allows quick replacement of units without sending the entire system in for repair. The high level of service is the hallmark of NT-MDT SI, which is confirmed by the feedback from many users from all over the world. All this together allows to reduce the downtime of the equipment to a minimum. nine0053 - Immunity

The systems of active vibration isolation and passive acoustic protection built into ACM VEGA make it possible to operate the complex in conditions that are not optimized for precision equipment. The unique active temperature control system reduces thermal drifts to record low levels. - High performance

The automated positioning system allows for in-line measurements of arrays of samples up to 200×200 mm in size in a fully automatic mode. Optimized for fast scanning electronics, measuring head and software increase the performance of AFM VEGA compared to laboratory counterparts. nine0053

Optimized for fast scanning electronics, measuring head and software increase the performance of AFM VEGA compared to laboratory counterparts. nine0053

- Metrological compliance

The precision sensors of the piezoscanner and the XY table provide high positioning accuracy on the micro- and nanoscale. Verification of equipment is carried out using approved linear measures of period and height. - Suitable for environment

The design and materials used in ASM VEGA allow the system to be operated in clean rooms. nine0053 - Electrical Compliance

The control electronics comply with the European Declaration for Electromagnetic Safety (CE).

Specification

Measuring heads

AFM head for conventional AFM probes. Compatible with most commercial probes

Scanner

Type: Piezo Tube Scanner with Feedback Sensors (OS), Probe Scan

Scan area, XYZ: 100×100×10 µm or 2×2×0. 2 µm in high resolution mode

2 µm in high resolution mode

Feedback: available for XYZ directions

Control electronics noise <5 µV/√Hz

Probe-sample positioning

Type: motorized XYZ sample positioning

XYZ thermal drift: <0.2 nm/min

Movement area: 200×200 mm in XY, 30 mm in Z

Positioning accuracy: 1 µm in XY, 0.2 µm in Z

Positioning speed: 8 mm/sec in XY

Guidance: Automated multiple scans by user script, video image, 3D mouse

Approach: Intelligent soft approach algorithm

Optical sensor

Light source: 850 nm SLD with FC single-mode fiber connector, optional LDM and SLD multi-wavelength sources

Optical System Tuning: Automated

Cantilever Bend Detection Sensor Noise: <25 fm/√Hz above 50 kHz

Video Surveillance Module

Type: Motorized focus, step zoom and XY positioning. Calibration by sample and laser position

Resolution: 0.98 µm

Field of view: up to 1.2 x 0.8 mm (5 MP)

Autofocus: on cantilever, on sample

Accessories

Sample holder set

nine0007

+/- 150 V voltage expander External signal access module

AFM probes: AFM probe holder supports most commercial probes

Control electronics and software

Supports up to 24 independent scan channels simultaneously

Signal processing: 512Mb buffer size, 3x340MHz FPGA, 320MHz DSP

2 Synchronous detectors: analog LEDs, 3 digital LEDs (supports multi-frequency AFM techniques)

Oscillators: 6×32 bit digital oscillators, 4x for SD

Bias voltage: +/- 10 V AC and DC (independent sample and probe bias), +/- 150 V AC and DC (optional)

Self-test: automatic function test

Auto-configuration of advanced techniques

Automation capabilities: optical system setup, frame-by-frame scanning of a 200×200 mm area according to a given scenario, optical and AFM image overlay, panoramic optical view, work area saving, cantilever autofocus, sample autofocus

Programming tools: Nova PowerScript language, LabView integration, Database integration cantilever, sample autofocus

Acquired image database

Interface: USB

Instrument isolation

Thermal stabilization: built -in non -fiberly temperature stabilization with an accuracy of 0.